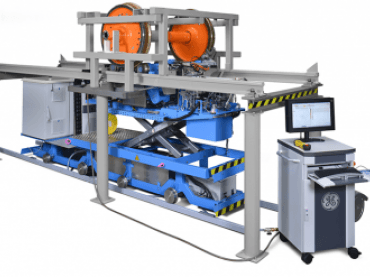

The WheelStar|UFPE design provides maintenance inspection of in-service railroad wheels without the need to remove the wheel sets from the train car.

The UFPE is integrated within maintenance shops and includes lifting and wheel rotation mechanics to facilitate below-grade inspection of wheel tread, face, flange and planar webs in a single test cycle. Phased array and conventional ultrasonic transducers optimize test results and a workflow oriented software suite guides the operator through the inspection process providing best-in-class usability.

• Excellent maintenance productivity without the need to remove wheeset from rail cars

• Proven flaw detection capability powered by GE´s industry leading USIP|xx ultrasonic inspection hardware

• Simple operation through an application specific graphical user interface with integrated PLC control

• Advanced analysis tools with projection view and suppression of geometric indications

• Remote controlled, battery powered trolley movement and wireless ultrasonic signal transmission to operator center

• Inspection of tread, face, flange and (straight) web areas in a single test cycle

– See more at: www.gemeasurement.com