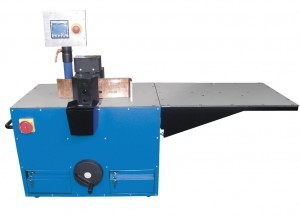

Station for bending, hole punching, offsetting Al and Cu busbars as well as inserting nuts:

• maximum busbar dimensions 12×125 mm

• bending angle range 0° ÷ 90°

Special features:

• equipped with smoothly adjusted bending angle sensor

• equipped with measuring rulers

• height adjustment of hole punching head (1mm precision)

• burr-free round and oval holes punching

Works with AH 500 or AH 550 electric hydraulic units.

Dimensions: (LxWxH): 790x530x498 mm; Weight: 110 kg (without equipment);

Force: 190 kN; Pressure: 630 bar

| Equipment | Type | SH 600 | SH 600-Platinum |

| Electric control cable (to work with AH 500 or AH550 electric hydraulic units) | SH 610 | √ | √ |

| Electronic adjustable angle indicator | SH 611 | √ | |

| Electronic control of operation selection and processing cycles | SH 612 | √ | |

| Insert for precise bending ( built-in encoder) | SH 401PLC-E | √ | |

| Insert for repeatable bending (buil-in limit switch) | SH 401PLC-K | √ | |

| Insert die for busbars offsetting | SH 406PLC | x | x |

| Round hole punch (standard dimensions according to catalog) | SH 403 | x | x |

| Oval hole punch (standard dimensions according to catalog) | SH 404 | x | x |

| Rectangular hole punch (dimensions according to order: max diagonal 21mm, side not shorter than 6,6mm) | SH 409 | x | x |

| Insert die for inserting nuts | SH 407 | x | x |

| Additional busbar support | SH 408 | x | x |

| Additional worktop | x | √ |

√ – standard equipment

x – additional equipment on request