GE’s planarCT module enables users of the phoenix microme|x and nanome|x X-ray inspection systems to perform better and more reliable inspection of solder joints and packages in complex printed circuit board assemblies.

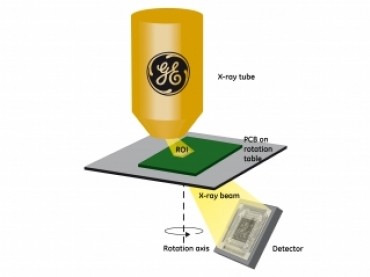

Performing a planarCT scan is easy to adjust without any sample preparation of fixing in a rotation stage. The board is just placed on the manipulation table and the region of interest scanned while the table rotates. The reconstructed planarCT slice or multislice views allow exact inspection results of a single plane or a whole package of interest without overlaying structures from other board areas. GE’s included 3D|viewer also allows full volume evaluation tasks.

planarCT is not just an excellent inspection method for printed circuit boards, but also for ROI inspection of large flat samples such as composites and additive manufactured parts enabling users to perform high resolving slice or multislice inspections without overlaying structures.

- 2D slice view provides significant better result quality compared to conventional X-ray inspection with overlaying features

- Excellent image quality and high magnification for wide defect coverage

- Slice and ROI CT volume evaluation in any direction with GE’s 3D|viewer

- Available with phoenix microme|x and nanome|x systems

- Upgrade option for already installed systems

– See more at: www.gemeasurement.com