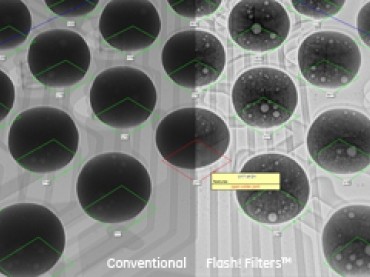

phoenix x|act is a large and powerful image processing software to program automatic test cycles. Manual as well as fully automated X-ray inspection can be done easy and self-explanatory. For manual X-ray inspection GE’s optional Flash! Filters™ image optimization technology enables faster, more reliable failure detection.

Features and Benefits

phoenix x|act is available in three different configurations: x|act base, x|act operator and x|act pro

CUSTOMER BENEFITS

- Extremely high defect coverage and repeatability to ensure highest quality requirements

- Minimum setup time due to easy and fast CAD-data import and programming

- Time and money saving by using fully automated inspection strategies

- Once programmed, the inspection program is portable to all x|act compatible phoenix|x-ray systems

KEY FEATURES

- Highly efficient fully automated CAD-data import, programming and image processing (Xe²)

- Live 3D overlay of CAD and inspection results even in rotated oblique inspection views at extremely high magnification

- Optimized positioning accuracy due to 3D auto-referencing

- Advanced barcode reading Contrast enhancement with temperature stabilized digital DXR panels

ADDITIONAL FEATURES

- View based programming with automated image processing

- Automated save of results, images and X-ray sample map

- Review with quality|review

- Automated view creation from strategies

- Easy macro recording for intuitive programming of inspection tasks

- Easy teach in of positioning and image processing parameters

- All display settings will be saved with one click

- Enhanced sample map functions – once created, the sample map can be used for all boards of the same type

- Precise distance measurement in the X-ray image

- Different sharpen, smooth, morphologic and rank operator image filter

- Interactive toolkit Reference point function (fiducial)

- Programmable load position

– See more at: www.gemeasurement.com