Membrane Bioreactor (MBR) systems offer several operational and economic advantages compared to conventional wastewater treatment plants. By incorporating GE’s membrane technology, MBR systems eliminate the need for secondary clarifiers and tertiary treatment. This allows for increased performance with a smaller footprint.

With over two decades of ZeeWeed* membrane bioreactor experience, GE delivers advanced MBR solutions for your needs.

LEAPprimary* is an advanced primary wastewater treatment that combines separation, thickening and dewatering of primary solids in a single compact unit. LEAPprimary performs the same function as a primary clarifier and fine screen in the typical MBR plant. The figure below illustrates the performance advantages of combining LEAPprimary and LEAPmbr technologies

- Energy Savings: Reduce energy for biological treatment by 25% and enable energy recovery

- Cost Savings: Reduce primary treatment equipment for your MBR and save 20% to 40%

- Simplified Design: Combine primary solids separation, sludge thickening and dewatering in one compact step

- Guaranteed reliability: extend membrane life with enhanced influent solids screening.

- Small footprint: Achieve advanced primary treatment in as little as 1/10 the footprint of conventional system

Featured Video

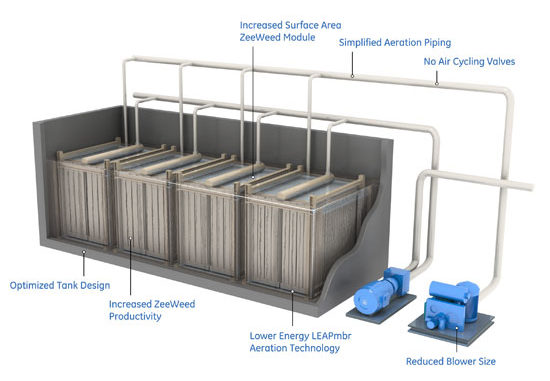

LEAPmbr* builds on 25 years of membrane bioreactor experience to deliver the most advanced MBR solution to date. It dramatically lowers energy costs, increases productivity, and offers a flexible design that can fit within a smaller footprint than conventional MBR technology. See how GE offers our wastewater treatment customers the lowest cost of ownership in the industry.

At its core, LEAPmbr uses our leading ZeeWeed* membrane while incorporating significant innovations that take wastewater treatment to the next level.

- Boost your productivity15% with our latest ZeeWeed membrane.

- Save on construction costs with a flexible design that reduces your membrane bioreactor footprint by 20%.

- Simplify your design by reducing membrane aeration equipment and controls by 50%.

- Reduce your operating costs with a 30% energy savings.

- Have the confidence of the strongest, most reliable membrane in the industry.

Stockholm Vatten will become the largest MBR plant in the world.

Stockholm Vatten will use GE LEAPmbr equipment for the Henriksdal municipal wastewater treatment facility to upgrade the existing technology. Once the upgrade is complete, the Henrickdal plant will process up to 864 million liters of wastewater per day. Watch the video here.

GE’s immersed ZeeWeed 500 membrane is specifically designed for difficult-to-treat water sources. Drinking water, wastewater, water reuse, and industrial applications can all benefit from GE’s strongest ZeeWeed membrane to produce water with very high purity and low silt density.

With more than two decades of membrane design experience, GE has optimized the ZeeWeed 500 membrane to improve flux, achieve greater permeability, reduce energy consumption, and increase membrane lifespan.

- Highest solids tolerance of any hollow-fiber membrane

- Works through virtually any raw water quality change or upset

- Outside-in flow path provides a more robust system

- Fully automated for simplified design and operation

- Outstanding technology for virtually all wastewater treatment applications – from greenfield plants to retrofits to water reclamation projects

- Second stage to obtain higher recoveries

Arizona water treatment facility recently retrofitted with GE’s ZeeWeed 500D membrane

EPCOR’s water treatment facility provides drinking and wastewater treatment for the town of Anthem, Arizona. See how the upgrade to GE’s ZeeWeed 500D technology allowed EPCOR to improve plant efficiencies.

GE’s immersed ZeeWeed 1000 ultrafiltration (UF) membrane system is ideal for retrofits and large plants. It is applicable in direct filtration, coagulation, tertiary filtration, multi-media filter retrofits, and pretreatment for reverse osmosis.

With GE’s ZeeWeed 1000, you can produce a water quality that meets stringent EPA drinking water standards while using less chemicals, reducing physical footprint, and producing less residual waste than a typical conventional potable water treatment system.

- High efficiency design ensures low capital, operating, and lifecycle costs

- Hollow-fiber geometry provides a greater filtration surface area, which reduces plant footprint and more effectively distributes cleaning solutions

- Cassettes are fully integrated with permeation and aeration connections, minimizing loose components and external connections

- Building block design reduces the size and cost of large plants and simplifies operation due to fewer process components and connections

- Flexible cassette design allows for cost-effective retrofits of filter basins of different shapes and sizes

- Cassettes and module materials are good for high salinity waters

How do ZeeWeed membranes work?

Watch a short animation to see how the GE’s ZeeWeed membranes work.

GE’s pressurized ZeeWeed 1500 membrane is ideal for drinking water treatment, tertiary filtration and pretreatment applications for brackish and seawater desalination.

This membrane utilizes low-fouling PVDF membrane chemistry, resulting in less frequent and less aggressive cleaning.

The ZeeWeed 1500 membrane is optimal for packaged plants with quick delivery and installation, and is also available as a custom solution engineered to specifications.

- High solids tolerance is capable of handling high turbidity spikes and coagulant doses

- Lower chemical usage over comparable systems

- Ability to retrofit other ultrafiltration (UF) and microfiltration (MF) systems

- Simple, automated operation

- Packaged and custom designs for greenfield or retrofit solutions

- Produce high-quality feedwater to enable RO systems to operate at peak performance with reduced fouling and less cleaning

- Enhance treated effluent quality from secondary wastewater treatment process

How do ZeeWeed membranes work?

Watch a short animation to see how the GE’s ZeeWeed membranes work.

GE’s ZW700B inside-out UF membranes use a blended polyethersulphone (PES), allowing the membrane to stay permanently hydrophilic and reduce the fouling tendency.

When compared to granular filter media and cartridge filters, the ZeeWeed* 700B membrane produces superior water quality and is virtually unaffected by variable raw water quality.

- Optimal removal of particulates, bacteria and viruses

- Uses SevenBore fiber technology with an inside-out flow orientation

- PES membrane fibers with 7 bores – provide high mechanical strength (10x that of single fibers) and ability to operate in a wide range of pH

- Typical applications include: pretreatment for reverse osmosis, high quality industrial process, non-water applications like juice, wine and beer clarification, high pressure offshore EOR and 4 log virus removal.