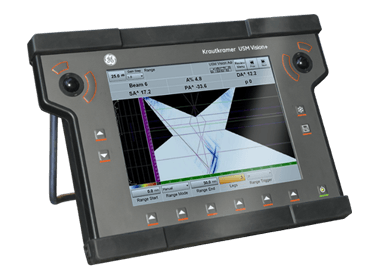

The Krautkramer USM Vision+ is everything you can expect from a phased array flaw detector. It combines high quality images with easy operation and can be used for a broad spectrum of applications such as weld, forgings, composites or corrosion inspection.

The instrument perfectly complements the expertise and experience of qualified Non-Destructive Testing (NDT) technicians, allowing them to use their skills to carry out comprehensive inspections, accurately and productively.

- High performance at your fingertips

You can use the Krautkramer USM Vision+ both in phased array and in conventional modes. Its 16/128 configuration allows USM Vision+ to be used in a wide variety of applications while complying with global inspection codes and standards. Inspection data is displayed on the instrument’s large, high resolution screen and you can also create instant reports using the on-board jpg function either on the instrument’s hard drive or on a connected USB flash drive.

- Designed for every environment

Developed to perform in harsh environments, the USM Vision+ has a certified and tested operating range of 0°C to +45°C. It even comes with an integrated stylus to support inspections where gloves are required. Its weight of just 4.5 kg (9.9 lbs) with batteries included makes it a truly portable instrument, while being also dust and humidity proof.

- Simple, intuitive operation

The industry-proven user interface will need no introduction for inspectors familiar with the USM family. However, the logical and intuitive parameter set-up enables new users to get off to a quick start too. There are two trackballs for fast access and easy pointing, as well as dedicated function buttons. All of this makes on-site set up, calibration and inspection simplicity itself.

The Krautkramer USM Vision+ is versatile enough to meet the inspection demands of a wide variety of applications:

- Weld inspection

- Forging and casting inspection

- Corrosion inspection

- Boiler tube inspection

- Composites inspection

– See more at: www.gemeasurement.com