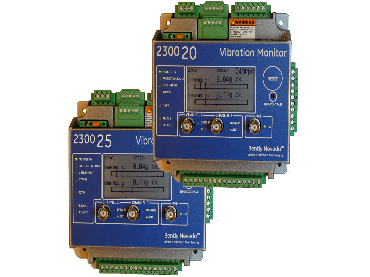

GE’s Bently Nevada 2300 Vibration Monitor Series provides cost-effective vibration monitoring and protection capabilities for non-critical machinery. It is comprised of the 2300/20 and 2300/25 monitors that are specifically designed to provide continuous monitoring and protection for Balance of Plant equipment.

With System 1 Evolution connectivity, The 2300 Vibration Series Monitors enable condition based maintenance of assets in a wide range of industries including: Oil & Gas, Power Generation, Water Treatment, Pulp & Paper, Manufacturing, Mining, Cement, and other industries.

Features and Benefits

The features and benefits of the 2300 Vibration Monitor Series include:

Next generation of low cost, entry level condition monitoring

State of the art electronics and signal processing

Delivers economical PdM condition monitoring and protection for low-and mid-level criticality assets

Continuous monitoring and protection

Self contained, compact, stand-alone vibration monitoring and protection, suitable for skid mounting

Robust, compact, self-contained two channel device

127 x 127 x 76 mm (5x5x3 in.) device size

Based on proven and reliable Bently Nevada 3500 monitor circuit design

State of the art electronics and signal processing

Low wiring and installation cost

Industry-leading number of measurements per channel with independent alert and danger set points

Key measurements (Direct, 0-pk, pk-pk, True RMS, Derived pk, integrated direct pk) real-time provided with alarm configuration

Convenient access to diagnostic data

Diagnostics and balancing capability using a portable data collector

Three 1:1 buffered transducer BNC outputs (vibration and speed signals) with short circuit and EMI protection

Key machine and monitor information clearly displayed at the monitor

Local monitor status LEDs

Local display showing overall values and speed

Overall data and event display

Quick and easy monitor configuration using Bently Nevada Monitor Configuration (BNMC) device configuration software

Low or high voltage power source

24VDC and optional 240/110V DIN rail mounted power supplies

Secure, tamper proof configuration management

Local configuration lockout and remote configuration lock (two dedicated discrete inputs)

Communications data pathway to other operating systems

Ethernet connectivity with Modbus functionality

Wide range of configuration options, including high vibration protection

Two dry contact relay outputs with programmable set points using BNMC

Easy-to-order with single part number kits

Higher signal fidelity

24-bit ADC conversion

Configurable 4-20 mA output available on the 2300/20 monitor

Trendmaster SPA interface configuration available on the 2300/25 monitor

Applications

The 2300 Monitor Series is specifically designed for essential balance-of-plant equipment with a wide range of industrial applications including, but not limited to:

Cooling tower fans

Pumps

Fans

Blowers

Motors

Pulverizers

Centrifuges

Mixers

Agitators

Air Compressors

Small reciprocating compressors

Small electric motors

Small hydro turbines

Hazardous Area Approvals

Approval Option (01) CSA, Canada and U.S. Class I, Division 2/Zone 2 ATEX: II 3G Ex nA nC [ic] IIC T4 Gc IECEx: Ex nA nC [ic] IIC T4 Gc

– See more at: www.gemeasurement.com